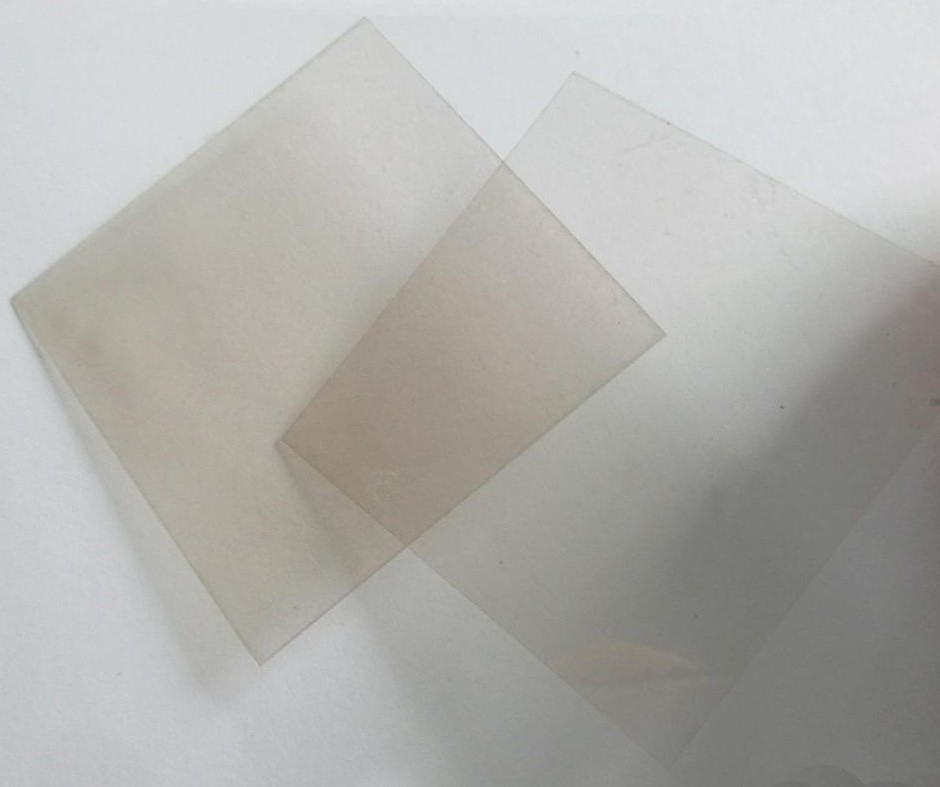

Mica Glass

Mica glass is derived from isinglass, a natural silicate mineral that can be used in older antique woods stoves, European stoves, coal stoves, furnaces, and even the boiler peepholes. It is a thin and transparent, having the appearance of cellophane or clear plastic. However, mica glass sheets can withstand temperatures of 1800° F, making it ideal for smaller windows on heating appliances. Our mica glass for wood stoves is available in a range of different precut sizes.

Mica glass is an innovative composite that amalgamates thin layers of natural mica minerals with glass. This fusion results in a material renowned for its remarkable attributes. Among its standout qualities is its capacity to withstand high temperatures and thermal fluctuations, making it an invaluable asset in environments where heat resistance is paramount.

With a thin and transparent appearance reminiscent of cellophane or clear plastic, mica glass can withstand temperatures of up to 1800°F.

Applications of Mica Glass

Mica Glass for Antique Wood Stoves: Mica glass sheets for antique wood stoves retains its resilience in the face of high temperatures, making it a durable choice that respects the authenticity of these treasured relics. As a testament to both aesthetics and endurance, mica glass captures the essence of antique wood stoves, offering a glimpse into bygone eras while maintaining a connection to modern standards of safety and performance.

Mica Glass for Furnaces and Boilers: Mica glass finds extensive use in industrial settings, particularly in furnaces and boilers. These applications expose glass to high temperatures that standard glass cannot endure. Mica glass, with its remarkable heat resistance, serves as a protective window, enabling operators to monitor processes while maintaining safety. Whether it's a furnace in a steel mill or a boiler in a power plant, mica glass ensures reliable operation under extreme conditions.

Mica Glass for Antique Coal Stoves: Mica glass plays a pivotal role in preserving the allure of antique coal stoves, marrying tradition with practicality. Antique coal stoves hold a unique place in history, embodying a bygone era's elegance and functionality. Mica glass, purposefully designed for enduring high temperatures, offers a clear view of the coal combustion process within these vintage stoves. Its ability to withstand the intense heat generated by burning coal ensures that enthusiasts can relish the charm of these stoves while maintaining safety.

Mica Glass for Industrial Applications: Mica glass sheets emerge as a stalwart in the industrial landscape, where its exceptional properties find applications across a spectrum of sectors. The fusion of mica minerals with glass yields a material that thrives in high-temperature environments, making it a crucial component in various industrial settings. Industries such as metallurgy, energy, and manufacturing rely on mica glass as a thermal window, enabling real-time observation of critical processes within furnaces, boilers, and reactors. Its resilience to thermal shocks ensures stability in dynamic conditions, while its transparency facilitates visual monitoring without compromising safety.Mica glass stands as a testament to the marriage of innovation and functionality. Its capacity to endure high temperatures while retaining transparency makes it an invaluable material in diverse applications. Whether it's adding a touch of elegance to a wood stove, enhancing the allure of lighting fixtures, or ensuring the longevity of stove glass, mica glass emerges as a versatile and reliable choice.

By grasping the essence of mica glass and exploring its manifold applications, consumers can confidently navigate the realm of specialized glass solutions. Armed with knowledge, you're empowered to make the right choice – ensuring that your investment in mica glass is not only visually appealing but also tailored to your specific requirements.

Mica Glass Sizing

Our mica stove glass comes in thicknesses of .003 inch to .005 inch. Individual sheets are offered only in the variety of sizes shown here. It is more economical to get several smaller panels and piece them together for larger window openings rather than trying to obtain a custom size. If you need smaller dimensions than what we offer, mica can easily be cut to size with scissors.

Please Note: These are the only sizes available; if you need to cover a larger area, you will need to piece multiple mica glass panels together.

Care and Maintenance

Mica glass, also known as isinglass, is a thin transparent sheet of silicate minerals. Because this material is highly resistant to extreme temperatures and less likely to shatter under these conditions, it is perfect for use in small windows on furnaces, heating stoves, and peepholes in boilers. Care and maintenance is easy:

- Gently rinse off the isinglass window with clean water.

- Dilute approximately 1 pint of water with 3 drops of mild non detergent soap.

- Wash the isinglass with a soft cloth and soapy water solution.

- Rinse thoroughly with fresh, clean water and another clean soft cloth.

- Dry the window with a third clean absorbent cloth or towel.

FAQ's

Q: What is mica stove glass, and how is it made?

A: Mica glass is a composite material crafted by laminating thin layers of natural mica minerals between layers of glass. This process results in a hybrid material known for its thermal resistance, transparency, and durability, making it suitable for various applications.

Q: Where is mica glass commonly used?

A: Mica glass finds diverse applications, notably in wood stoves, furnaces, boilers, and coal stoves. Its ability to withstand high temperatures makes it an indispensable component in industrial settings, enabling real-time process observation while maintaining safety.

Q: How does mica glass benefit wood stove users?

A: For wood stove users, mica glass offers a clear view of the flames while preventing sparks and heat from escaping. This transparency enhances the wood stove experience, while the glass's thermal resilience ensures long-lasting performance even in the presence of intense heat.

Q: Can mica glass be used in antique heating appliances?

A: Absolutely, mica glass is well-suited for antique wood and coal stoves. Its capacity to endure high temperatures allows enthusiasts to enjoy the nostalgia of vintage heating appliances while adhering to modern safety standards.

Q: What are the industrial applications of mica glass?

A: Mica glass serves as a thermal window in industries such as metallurgy, energy, and manufacturing. It enables real-time observation of processes within furnaces, boilers, and reactors, maintaining stability under varying conditions while providing essential transparency for monitoring purposes.